Centerline Tools & Design offers over 70 years of combined expertise in all areas of Progressive Metal Stamping. Centerline is dedicated to providing to our customers with the sourcing options they desire.

Centerline offers a cost competitive advantage to our customers due to our commitment to lean manufacturing and low-overhead principles. Our employees are cross-functionally trained which reduces down-time. Centerline is able to deliver high-quality products at competitive pricing and has all the capabilities you are looking for.

Capabilities

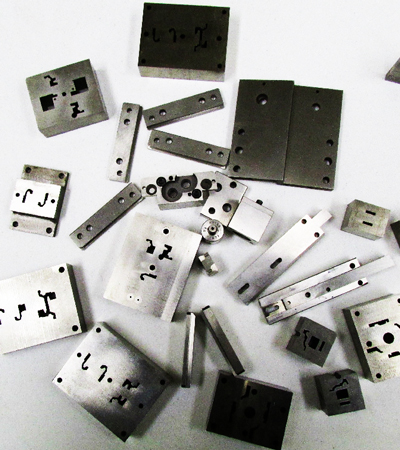

- Die/Fixture Design & Construction

- In-Die contacting

- Redesign/Tool Repairs

- Regular Die Maintenance

- High Speed Carbide Dies

- Custom Fixtures

- Transfer Tooling, Die Design, Construction, Prototyping and Custom Applications.

- Prototyping

- Temp Tooling for Rapid Prototyping

- Short Run Tooling (Engineering Changes)

- Utilizing form die and Wire EDM blanks

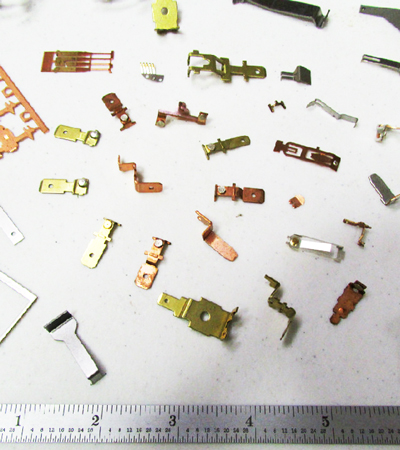

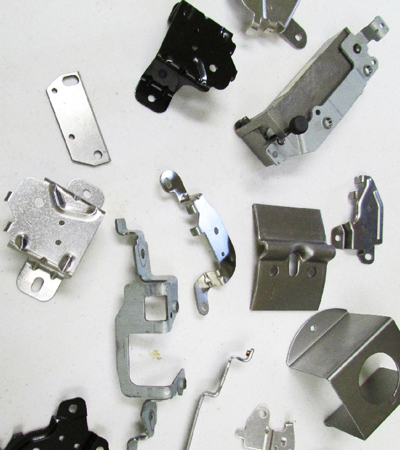

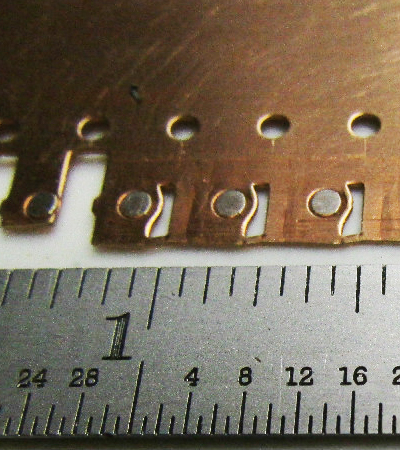

- Producing simple flat to complex formed parts

- Manufacturing Capabilities

- In-Die Contacting w/ speeds up to 200 SPM

- Up to 4 contacts per stroke

- In-Die Contact Welding

- .010 round or Formed Wire

- In-Die Tapping

- Press Capabilities – Centerline Tools can manufacture anywhere from one part up to millions of parts quickly and cost-effectively.

- From .003 to .125 in thickness

- Material up to 8″ wide

- Presses up to bed size of 36″ x 30″

We stamp parts in ferrous and non ferrous metals including stainless, carbon steels, brass, copper, aluminum and more.

- Secondary Operations – Centerline Tools offers a wide range of secondary operations that will assist in reducing cost and increasing efficiency and convenience for your supply chain.

- Assembly

- Custom Fixtures Operation

- Custom Packaging

- Spot Welding

- Secondary Forms/Piercings/Shears

- Heat Treating

- Plating – Ecoat

- Deburring

- Tapping

- Quality Assurance

- Provide Part History Cards

- Document customer critical dimensions for each production run

- Complete material Tracking History

- Complete Capability Studies

- SPC/PPAP/IMDS